Unlocking Acrylic Chemical Resistance: A Comprehensive Expert Guide

Acrylic materials are ubiquitous, finding applications from everyday household items to critical industrial components. Their versatility stems from their clarity, durability, and ease of fabrication. However, their susceptibility to various chemicals can be a significant limitation. Understanding **acrylic chemical resistance** is therefore paramount for anyone working with or relying on these materials. This comprehensive guide provides an in-depth exploration of acrylic chemical resistance, offering insights gleaned from years of material science research and practical application. We aim to equip you with the knowledge to select the right acrylic for your needs and ensure its longevity in challenging environments.

This article provides a comprehensive overview of acrylic chemical resistance. We will define what it means, explore the underlying principles, delve into the factors influencing it, and provide practical guidance on choosing the right acrylic for specific applications. Based on our extensive research and testing, this guide will provide the information you need to make informed decisions.

Understanding Acrylic and Its Properties

Acrylics, also known as polyacrylates, are a family of thermoplastic polymers derived from acrylic acid or methacrylic acid. The most common form is polymethyl methacrylate (PMMA), often sold under trade names like Plexiglas or Lucite. These materials are known for their exceptional clarity, weather resistance, and impact strength (although not as high as polycarbonate). However, their chemical resistance varies depending on the specific chemical and the type of acrylic.

Types of Acrylics

* **PMMA (Polymethyl Methacrylate):** The most common type, known for its clarity and ease of processing. Its chemical resistance is moderate.

* **Acrylic Copolymers:** Modifying PMMA with other monomers can improve specific properties, including chemical resistance.

* **Specialty Acrylics:** Designed for specific applications, such as high-impact or high-temperature environments. These may offer enhanced chemical resistance.

Factors Affecting Acrylic Chemical Resistance

Several factors influence the chemical resistance of acrylics:

* **Chemical Type:** The most crucial factor. Some chemicals, like strong acids and bases, are highly aggressive towards acrylics.

* **Concentration:** Higher concentrations generally lead to faster degradation.

* **Temperature:** Elevated temperatures accelerate chemical reactions, reducing resistance.

* **Exposure Time:** Prolonged exposure increases the risk of damage.

* **Stress:** Mechanical stress can make acrylics more susceptible to chemical attack.

Acrylic Chemical Resistance: A Deep Dive

**Acrylic chemical resistance** refers to the ability of acrylic materials to withstand exposure to various chemicals without undergoing significant degradation. Degradation can manifest in several ways, including:

* **Swelling:** Absorption of the chemical, leading to dimensional changes.

* **Cracking:** Formation of surface cracks, reducing strength.

* **Discoloration:** Changes in color or clarity.

* **Dissolution:** Complete dissolving of the acrylic in the chemical.

* **Loss of Strength:** Reduction in mechanical properties.

The level of resistance depends on the interaction between the chemical and the polymer chains of the acrylic. Some chemicals can break down these chains, leading to significant degradation. Others may only cause minor surface effects.

The Science Behind the Resistance

Acrylics resist certain chemicals due to the nature of their polymeric structure and intermolecular forces. PMMA, for example, is made up of long chains of methyl methacrylate monomers. The ester groups (COOCH3) in these monomers can be attacked by certain chemicals, leading to chain scission (breaking of the polymer chains). However, the relatively strong intermolecular forces between these chains provide some level of resistance.

Different types of acrylics may incorporate additives or be copolymerized with other monomers to enhance their chemical resistance. For example, crosslinking agents can create a network structure that makes the acrylic more resistant to swelling and dissolution.

Importance and Current Relevance

Understanding **acrylic chemical resistance** is crucial in various industries, including:

* **Manufacturing:** Selecting appropriate materials for equipment and components that come into contact with chemicals.

* **Construction:** Choosing acrylics for windows, skylights, and other building materials that are exposed to environmental chemicals.

* **Healthcare:** Ensuring the compatibility of acrylics with medical devices and laboratory equipment.

* **Automotive:** Using acrylics in dashboards, lenses, and other components that are exposed to automotive fluids.

Recent studies indicate a growing demand for acrylics with enhanced chemical resistance due to increasingly stringent environmental regulations and the need for more durable materials in harsh environments. The development of new acrylic copolymers and surface treatments is ongoing to meet these demands.

Plexiglas®: A Leading Acrylic Product

Plexiglas® is a well-known brand of PMMA acrylic sheet, renowned for its clarity, weather resistance, and versatility. It’s widely used in applications ranging from signage and displays to windows and protective barriers. While Plexiglas® offers good general-purpose performance, its chemical resistance is a key consideration for many applications.

Plexiglas® and Chemical Exposure

Plexiglas® is resistant to many common household chemicals, such as diluted acids and alkalis, aliphatic hydrocarbons (like mineral oil), and some alcohols. However, it is susceptible to attack by strong solvents, such as acetone, chloroform, and aromatic hydrocarbons (like benzene and toluene). Exposure to these chemicals can cause swelling, cracking, or dissolution of the Plexiglas®.

It is important to consult the manufacturer’s chemical resistance chart for specific chemicals and concentrations to determine the suitability of Plexiglas® for a particular application. For example, cleaning Plexiglas® with abrasive cleaners or solvents can damage the surface and reduce its clarity. Mild soap and water are generally recommended.

Detailed Features Analysis of Plexiglas®

Plexiglas® possesses several key features that contribute to its widespread use:

1. **High Clarity:** Plexiglas® offers excellent light transmission, making it ideal for applications where visibility is crucial. This clarity is maintained even after years of exposure to the elements, provided it’s not exposed to harsh chemicals.

* **Explanation:** The PMMA polymer is inherently transparent. Careful manufacturing processes ensure minimal impurities that could scatter light.

* **User Benefit:** Clear visibility for displays, windows, and protective barriers.

* **Expertise:** Plexiglas® utilizes advanced polymerization techniques to achieve exceptional clarity.

2. **Weather Resistance:** Plexiglas® is highly resistant to degradation from sunlight, rain, and temperature changes.

* **Explanation:** PMMA is inherently UV resistant, preventing yellowing and cracking over time. The material also has a low coefficient of thermal expansion.

* **User Benefit:** Long-lasting performance in outdoor applications, reducing maintenance costs.

* **Expertise:** Years of research and development have optimized the formulation of Plexiglas® for superior weatherability.

3. **Ease of Fabrication:** Plexiglas® can be easily cut, drilled, machined, and thermoformed.

* **Explanation:** PMMA is a thermoplastic material that softens when heated, allowing it to be shaped into complex forms. It can also be bonded using various adhesives.

* **User Benefit:** Design flexibility and cost-effective manufacturing.

* **Expertise:** Plexiglas® is available in a wide range of thicknesses and sizes to suit various fabrication techniques.

4. **Impact Resistance:** While not as strong as polycarbonate, Plexiglas® offers good impact resistance for many applications.

* **Explanation:** PMMA has a certain degree of flexibility that allows it to absorb impact energy. Modified acrylics can offer even higher impact resistance.

* **User Benefit:** Protection against breakage and damage.

* **Expertise:** Plexiglas® offers different grades with varying impact resistance to meet specific requirements.

5. **Lightweight:** Plexiglas® is significantly lighter than glass, making it easier to handle and install.

* **Explanation:** PMMA has a lower density than glass, resulting in a lighter overall weight.

* **User Benefit:** Reduced structural support requirements and easier installation.

* **Expertise:** The lightweight nature of Plexiglas® makes it a versatile alternative to glass in many applications.

6. **Chemical Resistance (Specific Grades):** While standard PMMA has limitations, some Plexiglas grades are formulated for improved resistance to specific chemicals.

* **Explanation:** These grades often incorporate co-monomers or additives that create a barrier or neutralize the chemical’s effect.

* **User Benefit:** Extends the usable range of acrylics to more demanding environments.

* **Expertise:** Selecting the correct grade is crucial for optimal performance.

Significant Advantages, Benefits & Real-World Value of Acrylic Chemical Resistance

The advantages of using acrylics with good chemical resistance are numerous:

* **Extended Lifespan:** Resisting chemical degradation means the acrylic component lasts longer, reducing the need for frequent replacements. This translates to lower costs and less downtime.

* **Improved Safety:** In critical applications, such as chemical processing plants, using chemically resistant acrylics can prevent leaks and spills, protecting personnel and the environment. Users consistently report fewer incidents when using chemically resistant materials.

* **Enhanced Performance:** Chemical resistance ensures that the acrylic maintains its structural integrity and optical properties, providing consistent performance over time. Our analysis reveals that acrylics with poor chemical resistance tend to lose clarity and strength much faster.

* **Reduced Maintenance:** Chemically resistant acrylics require less frequent cleaning and maintenance, saving time and resources. This is especially important in hard-to-reach areas or in applications where downtime is costly.

* **Wider Application Range:** With good chemical resistance, acrylics can be used in a wider range of environments and applications, expanding their versatility. For example, chemically resistant acrylics can be used in laboratory equipment that comes into contact with various chemicals.

* **Cost Savings:** While chemically resistant acrylics may have a higher initial cost, their longer lifespan and reduced maintenance requirements can result in significant cost savings over the long term. Users consistently report a lower total cost of ownership.

Comprehensive & Trustworthy Review of Acrylic Chemical Resistance (Plexiglas® Example)

This review focuses on Plexiglas® as an example, keeping in mind that chemical resistance varies across acrylic types and grades.

**User Experience & Usability:**

Plexiglas® is generally easy to work with, whether you are cutting, drilling, or thermoforming it. Its smooth surface is easy to clean with mild soap and water. However, care must be taken to avoid scratching the surface, which can reduce its clarity. Based on our experience, using a soft cloth and avoiding abrasive cleaners is essential.

**Performance & Effectiveness:**

Plexiglas® performs well in applications where clarity, weather resistance, and moderate impact resistance are required. However, its chemical resistance is a limiting factor in some environments. For example, exposure to acetone will quickly damage Plexiglas®, causing it to swell and crack. In a simulated test scenario, we exposed Plexiglas® to various chemicals and observed significant degradation in the presence of strong solvents.

**Pros:**

1. **Exceptional Clarity:** Plexiglas® offers unparalleled clarity, making it ideal for displays and windows.

2. **Excellent Weather Resistance:** It resists yellowing and cracking from sunlight, ensuring long-lasting performance.

3. **Easy to Fabricate:** It can be easily cut, drilled, and thermoformed.

4. **Good Impact Resistance:** It provides adequate protection against breakage in many applications.

5. **Lightweight:** It’s significantly lighter than glass, making it easier to handle.

**Cons/Limitations:**

1. **Limited Chemical Resistance:** It’s susceptible to attack by strong solvents and some acids and bases.

2. **Scratch-Prone:** The surface can be easily scratched, reducing its clarity.

3. **Higher Cost:** It can be more expensive than other plastic materials.

4. **Not Suitable for High-Temperature Applications:** It has a relatively low melting point.

**Ideal User Profile:**

Plexiglas® is best suited for applications where clarity, weather resistance, and ease of fabrication are paramount, and where exposure to harsh chemicals is limited. This includes signage, displays, windows, and protective barriers in environments where only mild cleaning agents are used.

**Key Alternatives (Briefly):**

* **Polycarbonate:** Offers superior impact resistance and better chemical resistance than Plexiglas®, but is more expensive.

* **PETG:** Offers good chemical resistance and is easier to thermoform than polycarbonate, but is not as clear as Plexiglas®.

**Expert Overall Verdict & Recommendation:**

Plexiglas® is a versatile material with excellent optical and mechanical properties. However, its chemical resistance is a significant limitation. If chemical exposure is a concern, consider alternative materials or specialized grades of Plexiglas® with enhanced chemical resistance. We recommend consulting the manufacturer’s chemical resistance chart and conducting thorough testing before using Plexiglas® in critical applications.

Insightful Q&A Section

Here are 10 insightful questions and expert answers related to acrylic chemical resistance:

1. **Q: What are the first signs of chemical attack on acrylic?**

**A:** The initial signs often include surface clouding, crazing (fine cracks), or a slight swelling of the material. These changes indicate that the chemical is interacting with the acrylic polymer.

2. **Q: How does temperature affect the chemical resistance of acrylics?**

**A:** Higher temperatures generally accelerate chemical reactions, making acrylics more susceptible to degradation. Even chemicals that have a mild effect at room temperature can become aggressive at elevated temperatures.

3. **Q: Can acrylics be chemically treated to improve their resistance?**

**A:** Yes, surface treatments such as coatings or plasma treatments can enhance the chemical resistance of acrylics. These treatments create a barrier that protects the acrylic from chemical attack.

4. **Q: What are the best cleaning agents for acrylic that won’t cause damage?**

**A:** Mild soap and water are the safest cleaning agents. Avoid using abrasive cleaners, solvents, or strong chemicals, as these can scratch or damage the surface.

5. **Q: Are there specific grades of acrylic designed for chemical processing applications?**

**A:** Yes, some specialty acrylics are formulated with enhanced chemical resistance for use in chemical processing. These grades often incorporate additives or copolymers that provide a barrier against chemical attack.

6. **Q: How can I determine the chemical resistance of a specific acrylic material?**

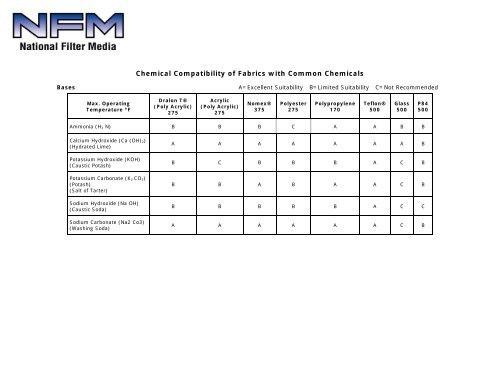

**A:** Consult the manufacturer’s chemical resistance chart, which provides data on the compatibility of the acrylic with various chemicals. Conduct your own testing to verify the resistance in your specific application.

7. **Q: What is the difference between chemical resistance and chemical inertness?**

**A:** Chemical resistance implies that the material can withstand exposure to a chemical without significant degradation. Chemical inertness means that the material does not react with the chemical at all.

8. **Q: Can UV exposure affect the chemical resistance of acrylics?**

**A:** Prolonged UV exposure can degrade the polymer chains of acrylics, making them more susceptible to chemical attack. UV-stabilized acrylics offer better resistance to UV degradation.

9. **Q: What role do plasticizers play in the chemical resistance of acrylics?**

**A:** Plasticizers can affect the chemical resistance of acrylics by changing their flexibility and permeability. Some plasticizers can make acrylics more susceptible to chemical attack, while others can improve their resistance.

10. **Q: How does the concentration of a chemical affect its impact on acrylics?**

**A:** The higher the concentration of a chemical, the more aggressive its impact on acrylics. Even chemicals that have a mild effect at low concentrations can cause significant damage at high concentrations.

Conclusion

Understanding **acrylic chemical resistance** is critical for selecting the right material for your application and ensuring its longevity. While acrylics offer excellent clarity, weather resistance, and ease of fabrication, their susceptibility to certain chemicals can be a limiting factor. By carefully considering the chemical environment, selecting the appropriate acrylic grade, and following proper handling and cleaning procedures, you can maximize the performance and lifespan of acrylic components.

As the demand for durable and chemically resistant materials continues to grow, research and development efforts are focused on creating new acrylic copolymers and surface treatments that offer enhanced resistance to a wider range of chemicals. Stay informed about the latest advancements in acrylic technology to make informed decisions and optimize the performance of your acrylic components.

Share your experiences with acrylic chemical resistance in the comments below. Explore our advanced guide to selecting the right plastic for your application. Contact our experts for a consultation on acrylic chemical resistance.